Technical Information

Technical Information Power And Control Cables

Power And Control Cables Power Appendixes

Power Appendixes Guide to the Wiring Regulations

Guide to the Wiring Regulations (Earth) Bonding solutions for the modern installation

(Earth) Bonding solutions for the modern installation صفحه (Earth) Bonding solutions for the modern installation

| (Earth) Bonding solutions for the modern installation | |

|

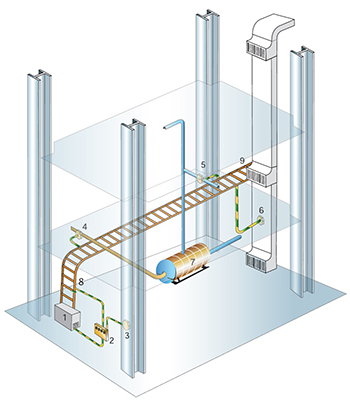

The question still remains as to how to carry out bonding in a modern installation . It was common to bond all exposed metalwork, including such items as metal window frames, individual metal foor or ceiling tiles and cross bonding to virtually everything . The modern trend is now well away from this, but the question remains of what to do about continuity of, say, the structural steel, or air conditioning ductwork systems. Commercial and industrial installations : See following Figures and accompanying notes. Using constructional elements for bonding |

|

| Figure 1. | Figure 2. |

|

|

|

KEY 1 >Main electrical switchpanel 2 >Main earthing terminal 3 >Bond to structure 4 >Bond to gas pipe system 5 >Bond to waterpipe system 6 >Bond to A/C ductwork 7 >Boiler 9 >Cable tray or ladder rack |

|

| Figure 3. | Figure 4. |

|

|

|

Figure.1 shows a typical solution which involves running separate bonding conductors to the extraneous-conductive-parts. This is unnecessary. Figure.2 shows a typical solution which involves running separate bonding conductors to the extraneous-conductive-parts but now installed on metal cable tray or ladder rack. This is often undertaken whether or not the tray or ladder rack was installed for power cables. Figure.3 shows a much better and more economic solution, where the cable tray or ladder rack has been used as a protective conductor. Figure.4 shows the best solution for most installations of this nature. The building structure has been used as a protective conductor. The cable tray is not shown on this diagram as it may have been installed for just a few cables, which have now been clipped directly to the structure. Unfortunately, this technique is under-utilized, mainly due to custom and practice. If the diagrams are considered again, it is obvious that the structure and metal services will form part of the bonding network whether you like it or not . |

|